News & Press Release

Receipt of the Award for Creativity in the 2025 Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology.

2025-6-10

Our engineers have received the Award for Creativity in the 2025 Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology of Japan.1

- 1This award is made at the commendation by the Minister of Education, Culture, Sports, Science and Technology, and was established in 1960 for outstanding workers who have contributed to advancement or improvement in science and technology in their occupational field by exercising remarkable creativity. It is given based on the Guidelines for the Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology constituted by the Ministry of Education, Culture, Sports, Science and Technology.

| Achievement | Recipients |

|---|---|

| Development of Generator Horizontal Stator Core Stacking Technique | Ryoichi Mashiko Shuji Hayase |

S. Hayase (left) and R. Mashiko (right)

Overview

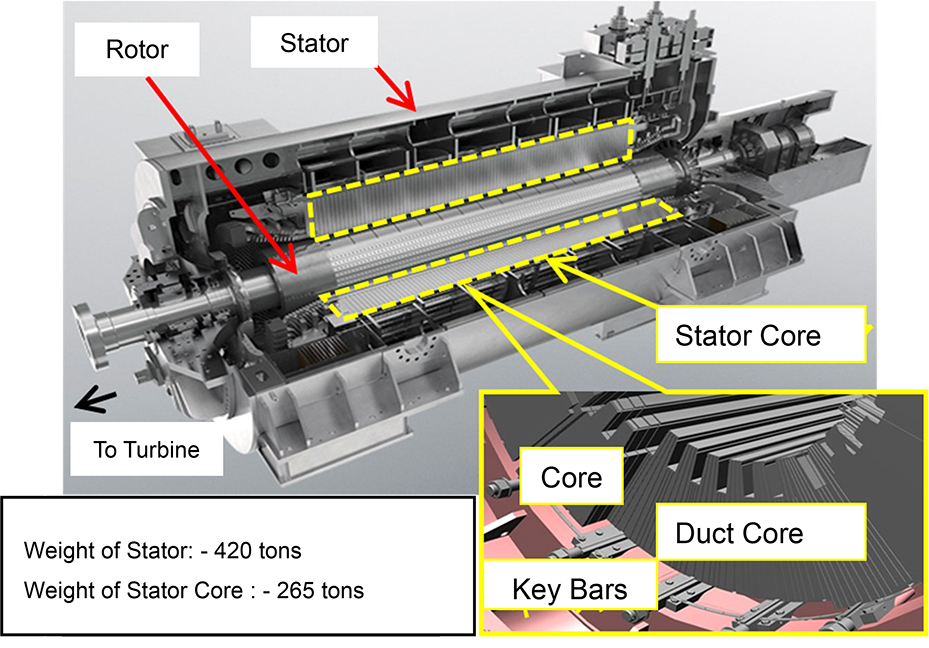

An electrical generator’s stator incorporates the stator core which is made up of laminated silicon steel sheets with a thickness of 0.35 mm or 0.5 mm. Each steel sheet is coated on both sides with insulating varnish. As this insulating varnish deteriorates over time, there are occasions on which stator core replacement becomes necessary.

Previously, replacement of an in-service stator core on site has been done by rotating the core from its installed horizontal position to an upright (vertical) position. Due to the typically limited workspace, the need to construct equipment for the replacement work, and other factors, this has been a difficult operation that is very costly and time-consuming for the generator’s owners. Thus, there has been an issue with replacing generator stator cores on site.

To solve this problem, we have developed a horizontal stator core stacking technique in which the stator core laminations can be replaced with the stator core able to be left in its installed horizontal position. This has made it possible to reduce the inconvenience of the on-site stator core replacement work for generators’ owners, and has also contributed to long-term stable operation of the generators.

The advanced technical capability represented by this development is an outcome of our ongoing efforts to date based on working in the generator business for many years. Mitsubishi Generator will continue to strive to provide high-quality, high-efficiency generators by improving and enhancing our technical capabilities, including this innovative technique, thereby contributing to the stable supply of electricity which is so essential for economic growth worldwide, and to the realization of a sustainable, decarbonized society.